Powered by a dependable Kohler gasoline engine, the Trailblazer 325 offers smooth and powerful welding performance with reduced noise and exceptional fuel economy. The machine’s advanced design ensures stable generator output, clean power for tools and electronics, and outstanding durability even in the harshest conditions. With its integrated GFCI protection, it also enhances operator safety by preventing electrical shocks during power generation and welding tasks.

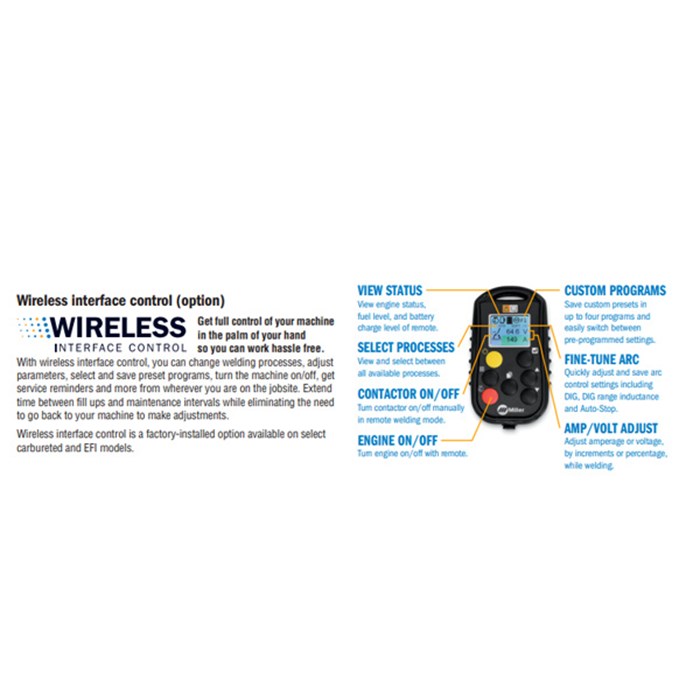

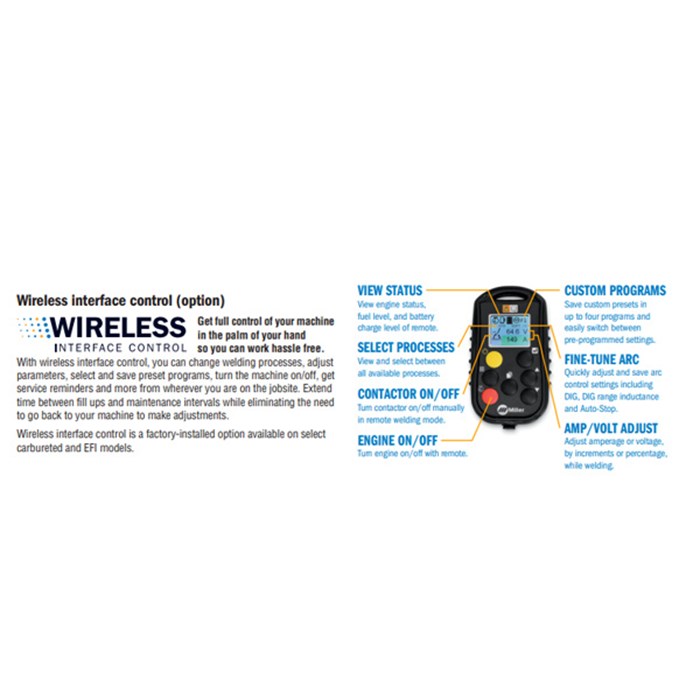

Trailblazer® welder/generators deliver unbeatable arc performance providing the smoothest, most stable arc in the industry. Now with optional Wireless Interface Control, you can work hassle-free with full control of the machine in the palm of your hand. The Trailblazer exclusive Auto-Speed™ technology delivers superior runtimes, increased fuel efficiency, and improved welder/generator performance. No other compact machine in the 300-amp class delivers more welding power or more auxiliary power with better fuel efficiency and less noise — for productive, profitable, quieter jobsites.

High-Performance Kohler Engine for Reliable Operation

At the core of the Trailblazer 325 lies a Kohler twin-cylinder gasoline engine known for its endurance, consistency, and low maintenance. This engine ensures clean combustion and delivers full power with minimal fuel usage. It starts easily in all weather conditions and runs quietly, thanks to Miller’s exclusive noise-reduction engineering.

The Kohler engine offers advanced torque characteristics that keep welding output steady, even during demanding applications. Its efficient fuel management system reduces operational costs while ensuring longer runtime between refueling. Maintenance is simple due to easily accessible oil, air, and fuel filters.

Professionals appreciate how this engine performs reliably in diverse work environments — from construction sites to field repairs — providing stable power and confidence that every weld will be clean and consistent.

Unmatched Arc Quality and Welding Precision

Miller’s engineering excellence ensures that every weld made with the Trailblazer 325 is of the highest quality. Its advanced technology provides a smoother, more stable arc than any other machine in its class. Operators can expect flawless performance across multiple welding processes, including Stick, MIG, TIG, and Flux-Cored.

The precise voltage and amperage control system minimizes spatter, improves puddle visibility, and enhances overall bead appearance. This machine provides rapid response to changes in arc length and maintains consistent output even during heavy-duty welding.

For professionals who value precision, the Buy Miller Trailblazer® 325 (Kohler), GFCI 907797001 offers total control over performance. The consistent DC output and steady arc ensure beautiful welds with minimal cleanup, saving both time and materials.

Simultaneous Welding and Power Generation

One of the Trailblazer 325’s standout features is its ability to provide generator power while welding. This dual functionality allows operators to run tools, lights, and other electrical devices without sacrificing welding performance.

The built-in generator delivers up to 12,000 watts of peak power, offering clean and stable current suitable for even sensitive electronic devices. This means you can power grinders, air compressors, or lighting systems directly from the same machine without worry.

This combination of welding and generator capability makes the Trailblazer 325 a true worksite powerhouse. It simplifies logistics, reduces fuel consumption, and eliminates the need for multiple machines.

For professionals seeking a more compact solution, you can also check out the MILLER BOBCAT 250 (KOHLER), GFCI Part#907500 — another reliable Miller model with proven durability and performance.

Quiet Operation for a Better Work Environment

Miller’s exclusive noise-reduction technology makes this model significantly quieter than traditional engine-driven welders. The advanced muffler system and improved engine design reduce noise emissions by up to 40%.

A quieter machine allows welders to communicate easily on-site, enhances concentration, and reduces operator fatigue. It also makes this welder suitable for urban projects, indoor facilities, and noise-restricted zones.

Smooth operation ensures minimal vibration, improving comfort during long shifts and reducing stress on internal components, leading to a longer machine lifespan.

Efficient Fuel System and Extended Runtime

The fuel efficiency of the Trailblazer 325 sets it apart from competitors. Its smart idle system automatically adjusts the engine speed based on load requirements. When no welding or power demand exists, the engine idles down, conserving fuel and reducing emissions.

This intelligent system extends runtime significantly while maintaining the ability to deliver full power instantly when needed. The result is lower operating costs, fewer refueling stops, and an eco-friendly machine that aligns with modern sustainability goals.

Professionals working long hours in the field find this feature invaluable because it helps maximize productivity while reducing fuel waste.

Compact and Portable Design for Easy Transport

Although powerful, the Trailblazer 325 maintains a compact structure that makes it easy to transport and install. Its balanced frame design and strategically placed lifting points ensure safe handling during loading and unloading.

The unit can be mounted easily on service trucks, trailers, or workshop floors. Its sturdy construction prevents tipping and absorbs vibration, ensuring stability even in rugged environments.

The combination of mobility and performance makes it an ideal solution for welders who frequently move between job sites or require flexibility without compromising output.

Rugged Build Quality for Harsh Conditions

Built to endure the toughest work environments, the Trailblazer 325 features a heavy-duty steel frame with a corrosion-resistant finish. Its sealed housing protects internal components from dust, debris, and weather exposure.

The optimized cooling system maintains consistent temperature control, preventing overheating and ensuring reliable performance even during extended use.

This machine exemplifies Miller’s commitment to durability. Every part is tested to withstand the rigors of industrial work, guaranteeing longevity and performance over years of use.

User-Friendly Controls for Precision and Simplicity

Miller designs every control system with ease and clarity in mind. The Trailblazer 325’s control panel features large, clearly marked dials and digital displays that allow operators to make quick adjustments.

Amperage and voltage settings are easy to fine-tune, and process selection is straightforward, reducing setup time. The GFCI outlets provide added protection against electrical faults, ensuring operator safety.

The simple, intuitive layout ensures that both experienced professionals and new operators can achieve precise results without complex adjustments.

Clean Power for Tools and Electronics

The generator produces low-distortion, clean electricity that’s safe for powering sensitive equipment. It maintains voltage consistency even under variable loads, providing dependable operation for grinders, fans, and lighting systems.

This makes the Trailblazer 325 ideal not only for welding but also as a primary or backup power source on construction and maintenance sites. Professionals value its ability to handle heavy tools and delicate electronics simultaneously with zero performance drop.

Multi-Process Flexibility for All Welding Needs

This model supports multiple welding processes, offering flexibility across materials and applications. Whether performing Stick welding for repairs, TIG for thin materials, or MIG for production work, the Trailblazer 325 adapts seamlessly.

The wide amperage range and refined voltage control make it suitable for everything from light fabrication to pipeline and structural welding. The machine’s precision and arc consistency ensure uniform welds, regardless of material thickness or position.

Professionals rely on it for its adaptability, as it eliminates the need for separate machines for different welding processes.

Low Maintenance and Long-Term Reliability

Maintenance simplicity is another hallmark of this model. The Kohler engine features accessible service points, allowing for quick oil, filter, and spark plug replacements. Extended service intervals reduce downtime, letting operators focus on work rather than machine upkeep.

Miller’s advanced cooling and air filtration systems keep the internal components protected from dirt and heat, maintaining long-term efficiency.

With regular care, this welder continues to perform reliably for years, making it a dependable investment for professionals seeking lasting value.

Technical Specifications and Highlights

-

Engine: Kohler twin-cylinder gasoline engine

-

Welding Output: 325A at 100% duty cycle

-

Welding Range: 20A–325A DC

-

Generator Power: 12,000 watts peak, 10,500 watts continuous

-

Voltage Control: Fine-tuned precision adjustment

-

Noise Level: Up to 40% quieter than comparable units

-

Cooling System: Air-cooled, high-efficiency airflow design

-

Weight: 490 lbs (portable and balanced)

-

Frame: Heavy-duty steel construction

-

Outlets: GFCI-protected 120V and 240V receptacles

Engineered for Professionals Across Industries

The Buy Miller Trailblazer® 325 (Kohler), GFCI 907797001 is designed for welders who need power, reliability, and precision in one machine. It’s widely used in industries such as construction, agriculture, fabrication, and field repair.

Contractors appreciate its portability and fuel efficiency, while industrial welders rely on its durability for large-scale operations. Fabrication shops use it as both a welder and generator, benefiting from its clean power and superior arc quality.

Its combination of modern technology, proven engine performance, and Miller craftsmanship makes it a top choice for professionals who expect more from their equipment.