Subscribe Now & Get 20% Discount!

Shopping cart (0)

Subtotal: $0.00

Spend $900.00 to get free shipping

Congratulations! You've got free shipping.

Menu

Categories

- Auto-Darkening

- Built-In Compressor

- CNC Plasma Cutters

- Engine Driven Welders

- Filler Metals

- Gardening

- Gas Welding & Cutting Equipment

- Hand tools

- Landscaping

- MIG Guns

- Mig Welders

- Multi-Process Welders

- Plasma Cutting Accessories

- Power tool

- Stick Welders

- Tig Welders

- Used Miller and Lincoln Welders for Sale

- Welder

- Welding Machine Accessories

- Welding Tools

- Woodworking

(214) 302-9319

support@weldingmachinesupply.com

Miller Bobcat 225 welder gener...

$4,232.00

Miller Trailblazer® 325 (Kohle...

$9,275.00

You can add any HTML here

We suggest you to create a Saved Template in Dashboard -> Templates -> Saved Templates and use it by switching content type above to Saved template.

Buy MILLER BOBCAT 250 (KOHLER), GFCI Part#907500 – Dependable Engine-Driven Welder and Generator for Professionals

The Buy MILLER BOBCAT 250 (KOHLER), GFCI Part#907500 is a high-performance, engine-driven welder and generator trusted by welders, fabricators, and field technicians worldwide. Designed with Miller’s signature engineering precision and powered by a reliable Kohler gasoline engine, this model delivers superior welding power, clean auxiliary electricity, and long-term durability. It’s perfect for professional applications that demand efficiency, portability, and exceptional performance — whether on construction sites, farms, or in industrial workshops.

This machine’s hallmark is its combination of welding strength and generator power. It produces up to 11,000 watts of clean AC power, capable of running tools, lighting, or even sensitive electronics while welding. Built with a rugged frame and simple, user-friendly controls, it provides reliability and performance that lasts for years. The GFCI receptacles enhance safety, protecting users and equipment from electrical hazards.

When you Buy MILLER BOBCAT 250 (KOHLER), GFCI Part#907500, you get more than just a welding machine — you gain a complete, self-contained power system engineered for the toughest work environments. With its balance of portability, strength, and advanced control, this model continues to be one of the most trusted and versatile engine-driven welders in its class.

MILLER BOBCAT 250 (KOHLER), GFCI Diesel Welder Part#907500

QUIETER AND BETTER SOUND

Significant improvements in sound level and quality offer better jobsite communication, which provides a safer, more efficient working environment for you and your crew. New Bobcat welder/generators have rotated the engine toward the front to create more efficient airflow, resulting in significantly quieter operation. Now you can start your job earlier in the day and end it later, as well as work around hospitals, businesses, and residential areas.

SMALLER AND LIGHTER DESIGN

New Bobcat welder/generators take up less space on trucks and trailers—leaving more room on your truck for other equipment and tools. Plus, they’re easier to move safely around jobsites—even with weld cables and running gear attached.

SMOOTH POWER – NOT SPIKE POWER

The revolutionary ten-degree skewed-rotor design optimizes generator performance for smoother power — not spiked power found with other brands. Better power — better performance

EASIER MAINTENANCE

With its intuitive design, the daily maintenance of our new Bobcat welder/ generators is faster and easier. With front panel maintenance displays, you know when your equipment needs to be serviced. And servicing is simple because of:

Oil checks that can be performed from the top by the front panel

Toolless panels that allow for quick access

Single-side fuel fill and oil drain/filter

DESIGNED FOR RELIABILITY

From Appleton, Wis. USA, our welder/generators are the most rugged, durable and long-lasting in the industry. We manufacture them to exceed requirements for extreme working conditions and they are hard-working from the core:

Copper windings and iron generator components for a quality-built machine

Lugged – not soldered – heavy internal leads for better field durability

Superior cooling technology for maximum performance and engine life

Super-tough armor to protect the welder/generator from accidental impact

Protective armor doors to cover the weld studs and receptacles as required by OSHA and CSA

for jobsite safety

Lift hook integrated into the center frame, which bolts to the machine’s base for greater durability

Long runtimes provide many hours of use before refueling is necessary

ACCU-RATED™ – NOT INFLATED GENERATOR POWER

Miller’s Accu-Rated™ 11,000 watts of usable peak power is delivered for a minimum of 30 seconds. Accu-Rated means peak power is usable for maximum generator loads such as plasma cutting, Millermatic® MIG welders and motor starting. Accu-Rated peak power beats the competition’s very short duration peak or surge power. Use your peak power; it’s more than a number.

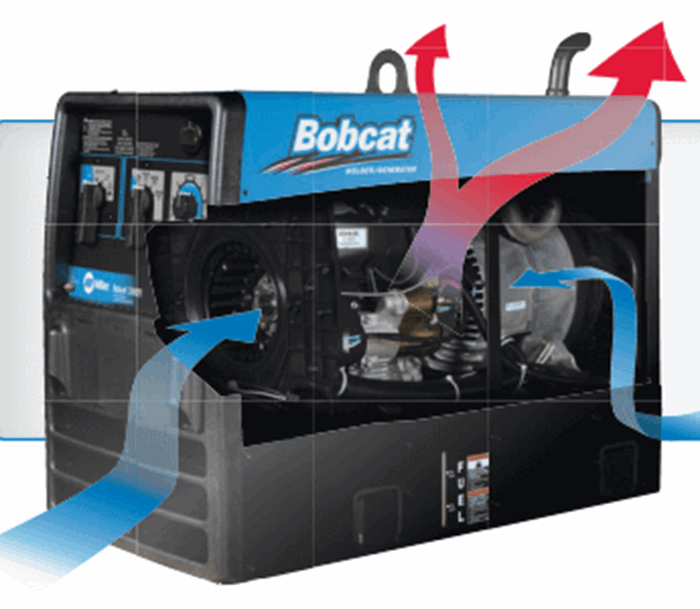

REVERSED GENERATOR AIRFLOW

Exclusive engine and generator packaging design operates cooler and more efficiently. The engine is rotated towards the front to create more efficient airflow. More efficient airflow and exclusive engine location are significant contributors to reduced sound level and size reduction. Hot air recirculation is eliminated when machine is mounted in tight spots, and internal parts are kept cool for optimal performance.

PROCESSES

MIG (GMAW)

DC TIG (DC GTAW)

Stick (SMAW)

Flux Cored (FCAW)

Air Plasma Cutting and Gouging (PAC) with Optional Spectrum Models

Air Carbon Arc (CAC-A) Cutting and Gouging

APPLICATIONS

- Construction

- Farm and Ranch

- Field Maintenance and Repair

- Stand Alone Generator

Powerful and Reliable Kohler Engine Performance

The Bobcat 250 features a Kohler CH730 twin-cylinder engine known for its efficiency and reliability. It produces consistent power output even under heavy load conditions, ensuring smooth welding and stable generator performance. The air-cooled gasoline engine starts easily, runs quietly, and requires minimal maintenance.

Kohler’s advanced design ensures long-lasting performance through efficient combustion and superior cooling. Welders appreciate its fast response to varying demands, whether welding thick materials or running auxiliary tools. Because the engine operates smoothly across all RPM levels, it minimizes vibrations and reduces wear on internal components.

The fuel system offers excellent economy and extended run times between refills, a feature that’s particularly beneficial for field jobs where continuous operation is critical. This engine not only saves time and fuel but also extends the life of the machine, making it a practical investment for professionals.

Exceptional Welding Performance and Arc Quality

Miller welders are known for smooth and steady arc performance, and this model upholds that reputation. The Bobcat 250 delivers reliable DC and AC output for Stick, MIG, TIG, and Flux-Cored welding processes. Its precise control system ensures consistent arc starts, deep penetration, and clean weld beads.

This machine can handle a wide range of materials, from mild steel and stainless steel to aluminum. Welders can easily adjust the amperage and fine-tune voltage settings to match the requirements of each project. The arc remains stable even when auxiliary power is used simultaneously — an advantage that sets this welder apart from many competitors.

With its advanced design, the Bobcat 250 eliminates the frustration of arc fluctuation or spatter, allowing welders to produce professional-grade results every time. The control and precision it offers make it an excellent choice for fabrication, repair, and construction applications.

Dual Functionality: Welding and Power Generation

This machine combines the best of both worlds — a powerful welder and a dependable generator. The generator produces up to 11,000 watts of continuous AC power, ideal for running grinders, drills, air compressors, and even lights on the job site.

Its clean power output is safe for sensitive electronics like laptops and measuring instruments. You can weld while using the generator, maintaining consistent voltage and current for both tasks. This efficiency makes it indispensable for remote projects where access to electricity is limited.

Professionals who rely on consistent, portable power appreciate this dual capability. It saves space, reduces costs, and eliminates the need for a separate generator, allowing welders to stay productive no matter where they work.

If you’re interested in a larger, diesel-powered option with extended performance capacity, check out the Miller Big Blue® 400 Pro (Kubota) #907732 — another excellent model built for industrial-grade reliability.

Compact and Portable Design for Field Mobility

Despite its strong performance, the Bobcat 250 remains remarkably compact. Its balanced structure allows for easy transport and installation, whether mounted on trucks or trailers. The ergonomic handles and secure lifting points simplify movement across job sites.

Portability matters for professionals who often relocate between projects, and this model provides exactly that. Its compact size and lightweight frame make it one of the most mobile welders in its category, allowing quick setup and reduced downtime.

Additionally, its sturdy base prevents tipping or vibration, ensuring stable operation even on uneven ground. With this machine, welders gain true mobility without sacrificing power or performance.

Durable Build Quality for Harsh Conditions

Miller designed the Bobcat 250 with long-term durability in mind. The outer shell is made of high-grade steel with a corrosion-resistant finish that withstands exposure to weather, dirt, and debris. The reinforced internal components provide stability and protection during transport and use.

This heavy-duty design ensures years of dependable service, even in extreme environments like construction sites and remote field operations. The cooling system promotes efficient airflow, keeping temperatures consistent during extended operations.

Welders who value reliability in tough situations consistently choose this machine because it keeps working when other welders stop. Its design clearly shows why Miller welders are considered industry standards for dependability.

Easy-to-Use Controls and Clear Display

Miller’s control layout has always emphasized simplicity, and the Bobcat 250 is no exception. The large, easy-to-read gauges and well-marked dials make setup fast and straightforward. Operators can adjust amperage, voltage, and process type in seconds.

The control panel includes clear indicators for fuel, output levels, and engine performance. This layout minimizes setup time and makes it easy to monitor welding parameters during operation. Welders can focus on precision and efficiency instead of dealing with complicated electronics.

The inclusion of GFCI-protected outlets enhances safety, ensuring electrical stability during power generation. It’s a simple yet powerful design that professionals trust for its ease and functionality.

Low Noise Operation for Better Work Environments

Noise reduction technology makes this model significantly quieter than older welders. The efficient muffler system lowers decibel levels, improving communication on-site and reducing fatigue.

Quiet operation is not only comfortable but also essential for job sites in residential or indoor areas where noise restrictions apply. The reduced sound level makes this welder a preferred choice for environments that prioritize worker safety and comfort.

This quieter performance doesn’t compromise output or power — it’s simply engineered smarter, keeping the job site peaceful while maintaining full efficiency.

Efficient Fuel System and Extended Runtime

Fuel efficiency remains one of the biggest advantages of this model. The Kohler engine’s optimized fuel injection ensures complete combustion, minimizing waste and extending runtime.

Automatic idle control lowers engine speed when power demand decreases, reducing fuel consumption even further. This feature extends tank life, cuts costs, and supports longer continuous operation between refills.

With this kind of economy, welders can spend more time working and less time managing fuel logistics, making it a top choice for field professionals seeking performance and practicality.

Stable and Clean Power Output for Tools and Electronics

The generator produces clean, low-distortion electricity that’s safe for sensitive equipment. It maintains voltage stability under fluctuating loads, ensuring uninterrupted performance for lights, grinders, and electronic tools.

Professionals appreciate how the clean power output prevents tool damage and improves consistency. Whether used in a fabrication shop or outdoor construction site, it keeps operations smooth, reliable, and safe.

The availability of multiple outlets also adds flexibility, allowing several tools to operate simultaneously without overload concerns.

Rugged Efficiency and Long-Term Dependability

Every part of the Bobcat 250’s design contributes to its long-term value. Its sturdy engine, reinforced frame, and efficient cooling system combine to reduce downtime and extend operational life.

Welders who depend on their equipment every day recognize the Bobcat’s superior build quality. With proper maintenance, it continues delivering professional-grade results for years — making it one of the most cost-effective investments in any professional’s toolkit.

Technical Specifications and Highlights

-

Engine: Kohler CH730 twin-cylinder gasoline engine

-

Welding Output: 40A–250A DC/AC

-

Duty Cycle: 100% at 225A

-

Generator Output: 11,000 watts peak, 9,500 watts continuous

-

Fuel Tank Capacity: 12 gallons

-

Noise Level: Up to 30% quieter than previous models

-

Cooling System: Air-cooled for consistent operation

-

Weight: 500 lbs (light for its class)

-

Frame: Steel with corrosion-resistant finish

-

Outlets: GFCI-protected 120V and 240V AC receptacles

Engineered for Professionals Across Industries

The Buy MILLER BOBCAT 250 (KOHLER), GFCI Part#907500 delivers unmatched versatility for various industries. It’s widely used in construction, agriculture, maintenance, and industrial fabrication.

Farmers depend on it for equipment repair, while pipeline contractors rely on its portability and power for field welding. Fabrication shops value its consistent arc performance and generator capacity for simultaneous tool operation.

Wherever you work, this model’s reliability, clean power, and user-friendly controls make it an indispensable part of your welding setup.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

MILLER BOBCAT 250 (KOHLER), GFCI Part#907500

$4,951.00

37 people are viewing this product right now

🔥 8 items sold in last 3 hours

MILLER BOBCAT 250 (KOHLER), GFCI Diesel Welder Part#907500

QUIETER AND BETTER SOUND

Significant improvements in sound level and quality offer better jobsite communication, which provides a safer, more efficient working environment for you and your crew. New Bobcat welder/generators have rotated the engine toward the front to create more efficient airflow, resulting in significantly quieter operation

Estimated delivery:5 days

Buy MILLER BOBCAT 250 (KOHLER), GFCI Part#907500 – Dependable Engine-Driven Welder and Generator for Professionals

The Buy MILLER BOBCAT 250 (KOHLER), GFCI Part#907500 is a high-performance, engine-driven welder and generator trusted by welders, fabricators, and field technicians worldwide. Designed with Miller’s signature engineering precision and powered by a reliable Kohler gasoline engine, this model delivers superior welding power, clean auxiliary electricity, and long-term durability. It’s perfect for professional applications that demand efficiency, portability, and exceptional performance — whether on construction sites, farms, or in industrial workshops.

This machine’s hallmark is its combination of welding strength and generator power. It produces up to 11,000 watts of clean AC power, capable of running tools, lighting, or even sensitive electronics while welding. Built with a rugged frame and simple, user-friendly controls, it provides reliability and performance that lasts for years. The GFCI receptacles enhance safety, protecting users and equipment from electrical hazards.

When you Buy MILLER BOBCAT 250 (KOHLER), GFCI Part#907500, you get more than just a welding machine — you gain a complete, self-contained power system engineered for the toughest work environments. With its balance of portability, strength, and advanced control, this model continues to be one of the most trusted and versatile engine-driven welders in its class.

MILLER BOBCAT 250 (KOHLER), GFCI Diesel Welder Part#907500

QUIETER AND BETTER SOUND

Significant improvements in sound level and quality offer better jobsite communication, which provides a safer, more efficient working environment for you and your crew. New Bobcat welder/generators have rotated the engine toward the front to create more efficient airflow, resulting in significantly quieter operation. Now you can start your job earlier in the day and end it later, as well as work around hospitals, businesses, and residential areas.

SMALLER AND LIGHTER DESIGN

New Bobcat welder/generators take up less space on trucks and trailers—leaving more room on your truck for other equipment and tools. Plus, they’re easier to move safely around jobsites—even with weld cables and running gear attached.

SMOOTH POWER – NOT SPIKE POWER

The revolutionary ten-degree skewed-rotor design optimizes generator performance for smoother power — not spiked power found with other brands. Better power — better performance

EASIER MAINTENANCE

With its intuitive design, the daily maintenance of our new Bobcat welder/ generators is faster and easier. With front panel maintenance displays, you know when your equipment needs to be serviced. And servicing is simple because of:

Oil checks that can be performed from the top by the front panel

Toolless panels that allow for quick access

Single-side fuel fill and oil drain/filter

DESIGNED FOR RELIABILITY

From Appleton, Wis. USA, our welder/generators are the most rugged, durable and long-lasting in the industry. We manufacture them to exceed requirements for extreme working conditions and they are hard-working from the core:

Copper windings and iron generator components for a quality-built machine

Lugged – not soldered – heavy internal leads for better field durability

Superior cooling technology for maximum performance and engine life

Super-tough armor to protect the welder/generator from accidental impact

Protective armor doors to cover the weld studs and receptacles as required by OSHA and CSA

for jobsite safety

Lift hook integrated into the center frame, which bolts to the machine’s base for greater durability

Long runtimes provide many hours of use before refueling is necessary

ACCU-RATED™ – NOT INFLATED GENERATOR POWER

Miller’s Accu-Rated™ 11,000 watts of usable peak power is delivered for a minimum of 30 seconds. Accu-Rated means peak power is usable for maximum generator loads such as plasma cutting, Millermatic® MIG welders and motor starting. Accu-Rated peak power beats the competition’s very short duration peak or surge power. Use your peak power; it’s more than a number.

REVERSED GENERATOR AIRFLOW

Exclusive engine and generator packaging design operates cooler and more efficiently. The engine is rotated towards the front to create more efficient airflow. More efficient airflow and exclusive engine location are significant contributors to reduced sound level and size reduction. Hot air recirculation is eliminated when machine is mounted in tight spots, and internal parts are kept cool for optimal performance.

PROCESSES

MIG (GMAW)

DC TIG (DC GTAW)

Stick (SMAW)

Flux Cored (FCAW)

Air Plasma Cutting and Gouging (PAC) with Optional Spectrum Models

Air Carbon Arc (CAC-A) Cutting and Gouging

APPLICATIONS

- Construction

- Farm and Ranch

- Field Maintenance and Repair

- Stand Alone Generator

Powerful and Reliable Kohler Engine Performance

The Bobcat 250 features a Kohler CH730 twin-cylinder engine known for its efficiency and reliability. It produces consistent power output even under heavy load conditions, ensuring smooth welding and stable generator performance. The air-cooled gasoline engine starts easily, runs quietly, and requires minimal maintenance.

Kohler’s advanced design ensures long-lasting performance through efficient combustion and superior cooling. Welders appreciate its fast response to varying demands, whether welding thick materials or running auxiliary tools. Because the engine operates smoothly across all RPM levels, it minimizes vibrations and reduces wear on internal components.

The fuel system offers excellent economy and extended run times between refills, a feature that’s particularly beneficial for field jobs where continuous operation is critical. This engine not only saves time and fuel but also extends the life of the machine, making it a practical investment for professionals.

Exceptional Welding Performance and Arc Quality

Miller welders are known for smooth and steady arc performance, and this model upholds that reputation. The Bobcat 250 delivers reliable DC and AC output for Stick, MIG, TIG, and Flux-Cored welding processes. Its precise control system ensures consistent arc starts, deep penetration, and clean weld beads.

This machine can handle a wide range of materials, from mild steel and stainless steel to aluminum. Welders can easily adjust the amperage and fine-tune voltage settings to match the requirements of each project. The arc remains stable even when auxiliary power is used simultaneously — an advantage that sets this welder apart from many competitors.

With its advanced design, the Bobcat 250 eliminates the frustration of arc fluctuation or spatter, allowing welders to produce professional-grade results every time. The control and precision it offers make it an excellent choice for fabrication, repair, and construction applications.

Dual Functionality: Welding and Power Generation

This machine combines the best of both worlds — a powerful welder and a dependable generator. The generator produces up to 11,000 watts of continuous AC power, ideal for running grinders, drills, air compressors, and even lights on the job site.

Its clean power output is safe for sensitive electronics like laptops and measuring instruments. You can weld while using the generator, maintaining consistent voltage and current for both tasks. This efficiency makes it indispensable for remote projects where access to electricity is limited.

Professionals who rely on consistent, portable power appreciate this dual capability. It saves space, reduces costs, and eliminates the need for a separate generator, allowing welders to stay productive no matter where they work.

If you’re interested in a larger, diesel-powered option with extended performance capacity, check out the Miller Big Blue® 400 Pro (Kubota) #907732 — another excellent model built for industrial-grade reliability.

Compact and Portable Design for Field Mobility

Despite its strong performance, the Bobcat 250 remains remarkably compact. Its balanced structure allows for easy transport and installation, whether mounted on trucks or trailers. The ergonomic handles and secure lifting points simplify movement across job sites.

Portability matters for professionals who often relocate between projects, and this model provides exactly that. Its compact size and lightweight frame make it one of the most mobile welders in its category, allowing quick setup and reduced downtime.

Additionally, its sturdy base prevents tipping or vibration, ensuring stable operation even on uneven ground. With this machine, welders gain true mobility without sacrificing power or performance.

Durable Build Quality for Harsh Conditions

Miller designed the Bobcat 250 with long-term durability in mind. The outer shell is made of high-grade steel with a corrosion-resistant finish that withstands exposure to weather, dirt, and debris. The reinforced internal components provide stability and protection during transport and use.

This heavy-duty design ensures years of dependable service, even in extreme environments like construction sites and remote field operations. The cooling system promotes efficient airflow, keeping temperatures consistent during extended operations.

Welders who value reliability in tough situations consistently choose this machine because it keeps working when other welders stop. Its design clearly shows why Miller welders are considered industry standards for dependability.

Easy-to-Use Controls and Clear Display

Miller’s control layout has always emphasized simplicity, and the Bobcat 250 is no exception. The large, easy-to-read gauges and well-marked dials make setup fast and straightforward. Operators can adjust amperage, voltage, and process type in seconds.

The control panel includes clear indicators for fuel, output levels, and engine performance. This layout minimizes setup time and makes it easy to monitor welding parameters during operation. Welders can focus on precision and efficiency instead of dealing with complicated electronics.

The inclusion of GFCI-protected outlets enhances safety, ensuring electrical stability during power generation. It’s a simple yet powerful design that professionals trust for its ease and functionality.

Low Noise Operation for Better Work Environments

Noise reduction technology makes this model significantly quieter than older welders. The efficient muffler system lowers decibel levels, improving communication on-site and reducing fatigue.

Quiet operation is not only comfortable but also essential for job sites in residential or indoor areas where noise restrictions apply. The reduced sound level makes this welder a preferred choice for environments that prioritize worker safety and comfort.

This quieter performance doesn’t compromise output or power — it’s simply engineered smarter, keeping the job site peaceful while maintaining full efficiency.

Efficient Fuel System and Extended Runtime

Fuel efficiency remains one of the biggest advantages of this model. The Kohler engine’s optimized fuel injection ensures complete combustion, minimizing waste and extending runtime.

Automatic idle control lowers engine speed when power demand decreases, reducing fuel consumption even further. This feature extends tank life, cuts costs, and supports longer continuous operation between refills.

With this kind of economy, welders can spend more time working and less time managing fuel logistics, making it a top choice for field professionals seeking performance and practicality.

Stable and Clean Power Output for Tools and Electronics

The generator produces clean, low-distortion electricity that’s safe for sensitive equipment. It maintains voltage stability under fluctuating loads, ensuring uninterrupted performance for lights, grinders, and electronic tools.

Professionals appreciate how the clean power output prevents tool damage and improves consistency. Whether used in a fabrication shop or outdoor construction site, it keeps operations smooth, reliable, and safe.

The availability of multiple outlets also adds flexibility, allowing several tools to operate simultaneously without overload concerns.

Rugged Efficiency and Long-Term Dependability

Every part of the Bobcat 250’s design contributes to its long-term value. Its sturdy engine, reinforced frame, and efficient cooling system combine to reduce downtime and extend operational life.

Welders who depend on their equipment every day recognize the Bobcat’s superior build quality. With proper maintenance, it continues delivering professional-grade results for years — making it one of the most cost-effective investments in any professional’s toolkit.

Technical Specifications and Highlights

-

Engine: Kohler CH730 twin-cylinder gasoline engine

-

Welding Output: 40A–250A DC/AC

-

Duty Cycle: 100% at 225A

-

Generator Output: 11,000 watts peak, 9,500 watts continuous

-

Fuel Tank Capacity: 12 gallons

-

Noise Level: Up to 30% quieter than previous models

-

Cooling System: Air-cooled for consistent operation

-

Weight: 500 lbs (light for its class)

-

Frame: Steel with corrosion-resistant finish

-

Outlets: GFCI-protected 120V and 240V AC receptacles

Engineered for Professionals Across Industries

The Buy MILLER BOBCAT 250 (KOHLER), GFCI Part#907500 delivers unmatched versatility for various industries. It’s widely used in construction, agriculture, maintenance, and industrial fabrication.

Farmers depend on it for equipment repair, while pipeline contractors rely on its portability and power for field welding. Fabrication shops value its consistent arc performance and generator capacity for simultaneous tool operation.

Wherever you work, this model’s reliability, clean power, and user-friendly controls make it an indispensable part of your welding setup.

Buy more save more!

Buy from 2 to 4 items and get 10% OFF

on each productBuy from 5 to 8 items and get 15% OFF

on each productIn stock

- Free shipping on all orders above 50,00

- No hassle returns, 30 days return

- Next day delivery within your country

SKU:

a3f872363ca7

Categories: Engine Driven Welders, Welder

Tags: bobcat 250 gfci welder, buy miller bobcat 250 kohler gfci part907500, kohler engine welder, miller 250 amp welder, miller 250 field equipment, miller 250 kohler welder, miller 250 portable welding machine, miller 250 welding system, miller ac dc welder generator, miller bobcat 250 engine welder, miller bobcat 250 welder, miller bobcat generator, miller bobcat gfci welder, miller engine driven welder, miller engine welder for sale, miller field welder, miller industrial generator, miller portable welder, miller power generator welder, miller welding generator, Part Number: 907500

Your Payment is 100% Secure